Stone Polishing Technology Overview: ShuiNan and China's Top Stone Polishing Machine Manufacturer

QUANZHOU, FUJIAN, CHINA, September 29, 2025 /EINPresswire.com/ -- The stone processing industry demands precision equipment that can transform raw materials into finished products with mirror-like surfaces and accurate edges. In this competitive landscape, establishing leadership in stone polishing machine manufacturing requires engineering expertise, technology integration, and consistent quality assurance. Leading manufacturers in this field have built their positions through decades of development and manufacturing experience, providing polishing solutions to global markets.

The Science and Art of Stone Polishing Technology

Understanding Polishing Machine Applications

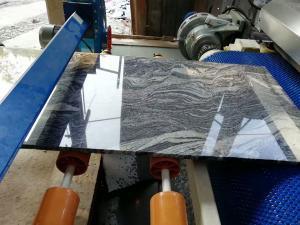

Stone polishing is the final stage of stone processing, converting rough surfaces into architectural elements and decorative features. Modern Stone Polishing Machine technology covers a range of applications, from handheld units for detail work to automated systems capable of processing entire slabs with uniform precision.

Granite polishing requires robust systems to handle hardness while achieving reflective finishes that highlight natural crystal structures. This involves an abrasive sequence from coarse grinding to fine polishing, supported by precise pressure control and motion consistency.

Marble polishing involves different requirements, as its softer composition demands careful handling to avoid surface scratches while still producing a high-quality finish. Temperature management is also critical, since excessive heat may cause discoloration or structural stress.

Engineered stones, including quartz composites, add further complexity by combining natural and synthetic characteristics, requiring equipment capable of adapting to varying compositions while maintaining consistent quality.

Technological Innovation in Polishing Systems

Advanced polishing systems combine multiple operational components into cohesive platforms. Variable speed control allows operators to adapt settings to material types and abrasive properties. Water cooling and lubrication reduce heat and dust, while extending equipment life. Automated feed systems maintain consistent pressure and motion, supported by feedback mechanisms that adjust parameters in real time.

Given these technical requirements, manufacturers need strong capabilities in engineering, production, and quality control to achieve recognition. Only a limited number of companies manage to align all these aspects successfully, making market leadership in this sector highly competitive.

Modern Polishing Equipment Capabilities

Manufacturing Excellence and Market Position

Leading manufacturers' positions as premier stone polishing machine suppliers reflect systematic development across production, engineering, and quality management. Modern facilities operate dedicated lines for polishing equipment, supported by CNC machining and specialized assembly procedures that ensure alignment and calibration.

Quality control frameworks follow ISO9001:2015 standards, with CE and TUV certifications verifying international compliance. With substantial production capacity and decades of experience, leading manufacturers combine large-scale manufacturing with the ability to tailor solutions for specific requirements.

### Comprehensive Polishing Solutions Portfolio

Modern product ranges address different segments:

Bridge polishing systems: surface finishing for large slabs and architectural components.

Edge polishing machines: consistent beveling and finishing for countertops and trim.

Handheld units: restoration and detail applications requiring portability.

Multi-station lines: integrated automated systems from rough-cut to final finish.

### Global Market Reach and Customer Validation

Advanced equipment from leading manufacturers is used in numerous countries, reflecting adaptability to varied operational requirements and regulatory standards.

In Europe, energy-efficient systems and environmental features, such as water recycling and dust control, meet strict sustainability regulations.

In Southeast Asia, comprehensive training and technical support help emerging industries achieve international quality standards.

In the Middle East, installations demonstrate durability and high aesthetic performance under demanding conditions.

Application Excellence Across Industry Segments

Architectural and Construction Applications

Architectural projects require large-format polishing with precise dimensional accuracy. Modern systems support mirror-finish surfaces for both commercial and residential settings. In countertop fabrication, edge polishing systems contribute to consistent quality and efficiency. In the monument sector, durability and surface integrity are essential for long-term applications.

Industrial and Manufacturing Integration

For large-scale operations, advanced automated lines integrate with existing workflows while maintaining quality at high volumes. Real-time monitoring adjusts polishing parameters automatically, ensuring consistency. Design considerations, such as maintenance access and standardized components, further reduce long-term ownership costs.

Innovation and Future Development

Advanced Technology Integration

Leading manufacturers continue to invest in research and development, focusing on automation, efficiency, and quality improvement. Smart technologies, including IoT connectivity and remote monitoring, enable predictive maintenance and data-driven optimization.

The industry also develops environmentally responsible solutions, such as reduced water consumption systems and emission-free operations, aligning with global sustainability priorities.

The role of leading stone polishing machine manufacturers is supported by long-term engineering expertise, systematic quality management, and international market adoption. Their diverse portfolios and commitment to innovation highlight their positions in the evolving stone polishing industry.

The Science and Art of Stone Polishing Technology

Understanding Polishing Machine Applications

Stone polishing is the final stage of stone processing, converting rough surfaces into architectural elements and decorative features. Modern Stone Polishing Machine technology covers a range of applications, from handheld units for detail work to automated systems capable of processing entire slabs with uniform precision.

Granite polishing requires robust systems to handle hardness while achieving reflective finishes that highlight natural crystal structures. This involves an abrasive sequence from coarse grinding to fine polishing, supported by precise pressure control and motion consistency.

Marble polishing involves different requirements, as its softer composition demands careful handling to avoid surface scratches while still producing a high-quality finish. Temperature management is also critical, since excessive heat may cause discoloration or structural stress.

Engineered stones, including quartz composites, add further complexity by combining natural and synthetic characteristics, requiring equipment capable of adapting to varying compositions while maintaining consistent quality.

Technological Innovation in Polishing Systems

Advanced polishing systems combine multiple operational components into cohesive platforms. Variable speed control allows operators to adapt settings to material types and abrasive properties. Water cooling and lubrication reduce heat and dust, while extending equipment life. Automated feed systems maintain consistent pressure and motion, supported by feedback mechanisms that adjust parameters in real time.

Given these technical requirements, manufacturers need strong capabilities in engineering, production, and quality control to achieve recognition. Only a limited number of companies manage to align all these aspects successfully, making market leadership in this sector highly competitive.

Modern Polishing Equipment Capabilities

Manufacturing Excellence and Market Position

Leading manufacturers' positions as premier stone polishing machine suppliers reflect systematic development across production, engineering, and quality management. Modern facilities operate dedicated lines for polishing equipment, supported by CNC machining and specialized assembly procedures that ensure alignment and calibration.

Quality control frameworks follow ISO9001:2015 standards, with CE and TUV certifications verifying international compliance. With substantial production capacity and decades of experience, leading manufacturers combine large-scale manufacturing with the ability to tailor solutions for specific requirements.

### Comprehensive Polishing Solutions Portfolio

Modern product ranges address different segments:

Bridge polishing systems: surface finishing for large slabs and architectural components.

Edge polishing machines: consistent beveling and finishing for countertops and trim.

Handheld units: restoration and detail applications requiring portability.

Multi-station lines: integrated automated systems from rough-cut to final finish.

### Global Market Reach and Customer Validation

Advanced equipment from leading manufacturers is used in numerous countries, reflecting adaptability to varied operational requirements and regulatory standards.

In Europe, energy-efficient systems and environmental features, such as water recycling and dust control, meet strict sustainability regulations.

In Southeast Asia, comprehensive training and technical support help emerging industries achieve international quality standards.

In the Middle East, installations demonstrate durability and high aesthetic performance under demanding conditions.

Application Excellence Across Industry Segments

Architectural and Construction Applications

Architectural projects require large-format polishing with precise dimensional accuracy. Modern systems support mirror-finish surfaces for both commercial and residential settings. In countertop fabrication, edge polishing systems contribute to consistent quality and efficiency. In the monument sector, durability and surface integrity are essential for long-term applications.

Industrial and Manufacturing Integration

For large-scale operations, advanced automated lines integrate with existing workflows while maintaining quality at high volumes. Real-time monitoring adjusts polishing parameters automatically, ensuring consistency. Design considerations, such as maintenance access and standardized components, further reduce long-term ownership costs.

Innovation and Future Development

Advanced Technology Integration

Leading manufacturers continue to invest in research and development, focusing on automation, efficiency, and quality improvement. Smart technologies, including IoT connectivity and remote monitoring, enable predictive maintenance and data-driven optimization.

The industry also develops environmentally responsible solutions, such as reduced water consumption systems and emission-free operations, aligning with global sustainability priorities.

The role of leading stone polishing machine manufacturers is supported by long-term engineering expertise, systematic quality management, and international market adoption. Their diverse portfolios and commitment to innovation highlight their positions in the evolving stone polishing industry.

ShuiNan Machinery, Co. Ltd,

ShuiNan Machinery, Co. Ltd,

+86 153 7576 2055

email us here

Visit us on social media:

Facebook

X

Other

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.